Nefab Packaging is a leader in innovative and green packaging solutions for over 70 years. It meets the needs of industries like Telecom, Energy, Aerospace, and Healthcare. The company ensures products are shipped safely and efficiently.

With a big presence in more than 38 countries and about 100 units worldwide, Nefab uses its knowledge to protect the environment. It also helps clients save money on packaging. On average, Nefab’s solutions cut costs by 20% and reduce carbon emissions by 31%.

Nefab has a team of over 200 engineers and many ISTA-Certified Engineering Centers. This team creates protective packaging that fits the needs of different industries.

Key Takeaways

- Nefab reduces total packaging costs by an average of 20%.

- The company offers sustainable packaging solutions that lower carbon footprints by 31%.

- Nefab has been in operation for over 75 years, optimizing industrial packaging.

- The company serves multiple industries including Telecom and Healthcare.

- Nefab provides protective packaging that meets unique logistical challenges.

- With a global presence, Nefab ensures consistency in supply chain solutions.

- Custom innovations in packaging support sustainability goals for businesses.

Introduction to Nefab Packaging Solutions

Nefab has been leading in Nefab packaging solutions for over 70 years. It started in 1949 by providing stackable plywood boxes to LM Ericsson in the 1960s. Nefab now offers a wide range of comprehensive solutions for packaging for many industries.

The Vikex box, introduced in 1968, was a big step forward. It was only 6 mm thick, making it much lighter and smaller than old wooden crates. This change helped a lot with air shipping, saving space and money.

Nefab quickly became a top packaging provider. It grew its market and showed the value of foldable packaging. This made a big difference for clients.

Today, Nefab is a global leader, working in over 30 countries with over 200 engineers. It invests a lot in research and development. Nefab has five ISTA test labs, including one in Son, Netherlands.

Nefab is all about quality and sustainability. It focuses on solving client problems and making supply chains better. As it celebrates 70 years in 2023, Nefab keeps helping many industries like telecom, aerospace, and health-tech.

Understanding Industrial Packaging Needs

Nefab Group has a solid base in meeting the varied packaging needs of different sectors. With over 70 years in the packaging field and a presence in more than 30 countries, Nefab offers custom solutions. These solutions are designed to fit the unique needs of each industry.

Industries like automotive, healthcare, aerospace, and telecom/datacom have special packaging challenges. They need strong protection during shipping and must follow strict rules. This calls for creative solutions to keep products safe and sound during transport.

EdgePak Straw is a great example of Nefab’s dedication to green solutions. This eco-friendly packaging can hold up to four tons. It helps save over 1,000 metric tons of CO2 each year for a big car maker. This shows how Nefab’s innovative designs meet packaging needs while saving money.

Nefab also focuses on sustainable practices in its work. This approach helps companies tackle packaging challenges while cutting costs. Nefab’s goal is to reduce costs by 20% and carbon emissions by 31%. This aligns with the current needs of the industry.

Tools like GreenCalc help Nefab measure the environmental effects of packaging. This shows their commitment to finding the best solutions for the supply chain. As Nefab keeps innovating, it’s key in shaping the future of packaging. It addresses both short-term and long-term needs across various sectors.

Nefab Packaging: Innovative and Sustainable Solutions

Nefab Packaging Solutions is all about being green. It started before the 1950s and has always aimed to protect products and the planet. They use eco-friendly materials and methods to cut down on carbon emissions in many fields.

Importance of Eco-Friendly Packaging

Eco-friendly packaging is now a must, not just a choice. Nefab uses recyclable stuff like corrugated paper and products made from agricultural waste. They work with universities and companies to keep improving. This way, they reduce waste, encourage recycling, and use sustainable materials.

Reducing Carbon Footprint with Nefab

Nefab’s solutions really help cut down on carbon emissions. For example, the EdgePak Collar cut CO2 emissions by 50% for some clients. Their GreenCALC Life Cycle Assessment Tool helps pick designs that are better for the environment. They want to save 10 million tons of CO2 in customer supply chains by 2026.

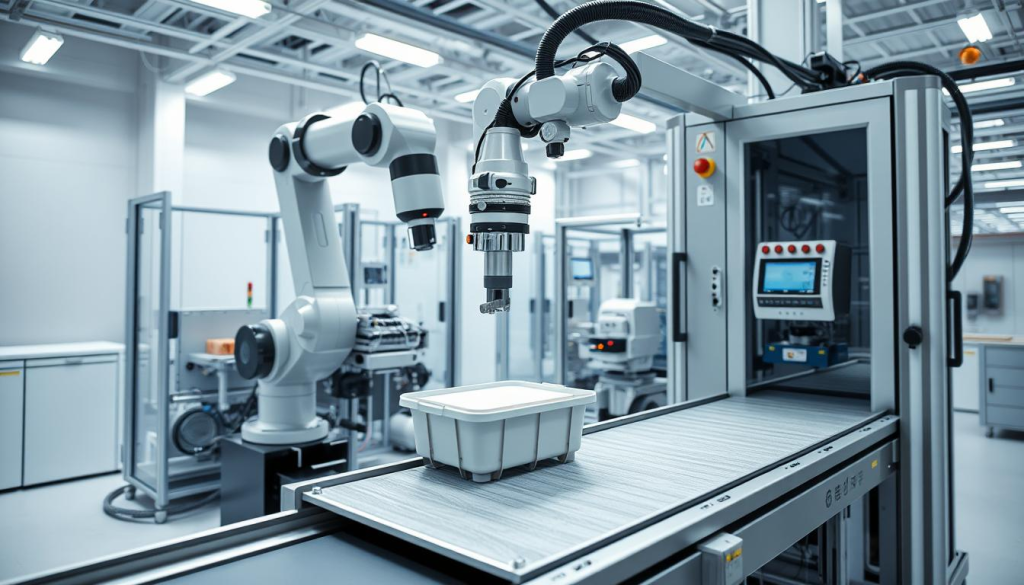

Custom Packaging Solutions for Various Industries

Nefab offers custom packaging solutions for different sectors. Each industry has unique packaging needs, like healthcare and telecom. Nefab focuses on innovation and sustainability, ensuring safety and efficiency.

Tailored Approaches for Healthcare Equipment

In healthcare, packaging is key to protect sensitive items. Nefab’s solutions keep medical devices safe and sterile during transport. They also cut down on costs and improve logistics.

Custom packaging keeps high-tech surgical robots and delicate tools safe. This ensures they arrive in good condition and ready to use.

Packaging Solutions for Telecom and Datacom

Telecom and datacom face challenges in protecting electronic components. Nefab offers strong packaging options for these products. Their solutions help keep products safe and efficient during transport.

Customizable trays save space, improving supply chain management. Nefab’s focus on sustainability reduces packaging waste, meeting industry standards.

Optimization of Supply Chain with Nefab Packaging

Nefab packaging solutions are key to a better supply chain. They are made to make goods flow smoothly, ensuring efficient logistics. With more demand for items like Lithium-ion Batteries, new packaging ideas are vital.

Using lightweight materials like plywood, Nefab cuts down on shipping costs. It also makes the most of space in shipments. The use of recycled materials in packaging helps the environment and reduces waste.

The need for Lithium-ion Batteries is expected to skyrocket. The global market could grow nearly 17 times by 2030. Nefab’s solutions help ship more batteries by making them lighter.

Nefab combines packaging with logistics to make a seamless system. This system helps spot and fix problems quickly. It also lets products be tracked in real-time, making decisions easier.

They also have a returnable packaging system. This saves materials and cuts down on costs as production grows. It’s a big help for regional expansion.

Nefab’s focus on safe transport of Lithium-ion Batteries is critical. It meets important rules for handling, packaging, and marking. With more automated logistics for battery transport, Nefab’s packaging is more important than ever.

As global shipping is set to increase, Nefab’s solutions are vital. They help make supply chain logistics better and support green efforts.

Advantages of Utilizing Nefab Packaging

Using Nefab packaging brings many benefits to companies looking to improve their logistics and supply chain. It helps cut costs and protect products better during shipping.

Cost Reduction Strategies Using Nefab

Nefab packaging helps save money by reducing waste and boosting efficiency. For instance, they use 30-40% recycled material in their products. This led to recycling 210,600 lbs of plastic trays in one project.

These efforts saved over $400,000 from recycling alone. They also saved $80,000 by reusing plastic pallets and lids. Companies can save almost 50% by adopting circular practices.

Enhanced Protection for Products During Shipping

Keeping products safe during shipping is key to keeping customers happy. Nefab’s solutions use materials wisely, lowering damage rates. They’ve added over 1 million pounds of reground plastic to their products this year.

This makes their packaging stronger. Nefab has also cut freight costs from $1,250 to $500 per truckload. This shows the big benefits of using Nefab packaging.

| Cost Reduction Initiatives | Environmental Impact |

|---|---|

| 210,600 lbs of plastic trays recycled | CO2 emissions reduced by 175 tons |

| Over $400,000 saved in costs from recycling | 3,029 cubic yards of waste diverted from landfills |

| Additional $80,000 from reusable pallets | 6,883 barrels of petroleum saved |

| Freight costs reduced from $1,250 to $500 | Elimination of environmental impact fees |

Logistics Integration: Bundling Services with Packaging

Nefab combines logistics and packaging into one service. This makes things simpler and improves teamwork. It offers a complete package to make the supply chain better.

The global contract logistics market is growing fast, at 4.62% by 2027. Most companies outsource their logistics, like transportation and warehousing. This shows the need for packaging that works well with logistics.

Nefab cares about the environment, just like 80% of top executives do. They make logistics and packaging better for the planet. This saves money and makes things more efficient.

Nefab uses new tech, like a Warehouse Management System, to cut costs and emissions. Their returnable packaging model shows their dedication to the environment. It also makes logistics better.

Nefab makes special packaging for industries like automotive. They use advanced methods to make packaging fast and efficient. This approach helps manage resources better and keeps the supply chain running smoothly.

Cutting-Edge Technology in Nefab Packaging

Nefab leads in using the latest packaging tech to meet tough industry needs. It has six ISTA Certified test labs worldwide, including in San Jose, United States; Wuxi, China; and Eindhoven, Netherlands. These labs help ensure products meet standards, avoiding legal issues and smooth customs clearance.

Nefab is all about innovation, making product development faster and cheaper. It tests products under real-world conditions, like drops and vibrations. This ensures products arrive safely and helps with insurance claims for any damage.

The company’s engineering test centers speed up product development. Nefab focuses on sustainable packaging, combining protection, eco-friendliness, and cost savings. It uses innovative materials like straw-based packaging and reusable trays, showing its commitment to a circular economy.

As Nefab celebrates its 75th year in 2024, it’s committed to sustainability and innovation. The need for green solutions is growing, pushing Nefab to use advanced tech. Its goal is to make the packaging industry more sustainable and connected.

Case Studies: Success Stories with Nefab Packaging Solutions

Nefab case studies show how good packaging can change things in many fields. They tell stories of how companies got better at keeping things safe, moving things smoothly, and saving money. These stories come from different places, like car making and supermarkets, showing how Nefab’s solutions work for everyone.

One big story is from the U.S. car makers. Nefab helped them use less packaging and save money on shipping. This made their work better and helped the planet too. It shows Nefab is all about making things better for everyone.

Nefab also worked with UK supermarkets to make their delivery chain better. They cut down on waste and kept products safe while moving. These stories are great examples of how Nefab can help other companies do the same.

Conclusion

In this Nefab packaging summary, we’ve looked at Nefab’s key role in industrial packaging. It’s all about innovation, being green, and focusing on customers. Nefab wants to cut down 10 million tons of CO2-equivalent emissions in customers’ supply chains by 2030. This shows its big commitment to eco-friendly solutions.

Nefab’s future packaging plans aim to cut down landfill waste and transport costs. It offers over 700 certified boxes for production. It also has a lot of experience in sectors like Lithium Battery Packaging. With tools like the GreenCalc Life Cycle Analysis (LCA) tool, Nefab helps customers reduce carbon footprint and save money.

In the world of industrial packaging, Nefab is leading the way. It’s adapting to changes in the market and rules. With trends towards local production and flexible packaging solutions, Nefab is ready to meet its clients’ needs. Nefab’s ongoing innovation makes the future of packaging look bright and green.

If you need packaging supplies, find VSL Packaging – Packaging company , 1, 2, 3, 4, 5

FAQ

What types of industries does Nefab provide packaging solutions for?

Nefab offers packaging solutions for many industries. These include Telecom, Vehicles, Energy, Aerospace, and Healthcare Equipment.

How does Nefab ensure sustainability in its packaging solutions?

Nefab makes its packaging sustainable. It uses recyclable materials and eco-friendly practices. This reduces carbon footprints by up to 31% and saves costs.

What are the advantages of using Nefab’s custom packaging?

Nefab’s custom packaging protects products better. It also lowers damage rates and saves money. Clients often see a 20% cut in expenses.

How does Nefab optimize supply chain processes for its clients?

Nefab improves supply chains by combining packaging and logistics. It removes bottlenecks and allows for real-time tracking and management.

What technologies does Nefab utilize in its packaging solutions?

Nefab uses advanced technology. It creates strong, efficient packaging that meets industry needs.

Can you provide examples of Nefab’s successful packaging solutions?

Yes, Nefab shares case studies. They show how clients have saved money, protected products, and improved logistics.

How does Nefab’s packaging support specific industry requirements?

Nefab designs packaging that meets strict regulations. It ensures safety during transit for industries like Healthcare, Telecom, and Aerospace.

What is the significance of logistics integration in Nefab’s offerings?

Nefab’s packaging and logistics services together streamline supply chains. They improve communication and efficiency.

How does Nefab protect products during shipping?

Nefab’s solutions focus on material efficiency and design. They provide the best protection for products during transport.